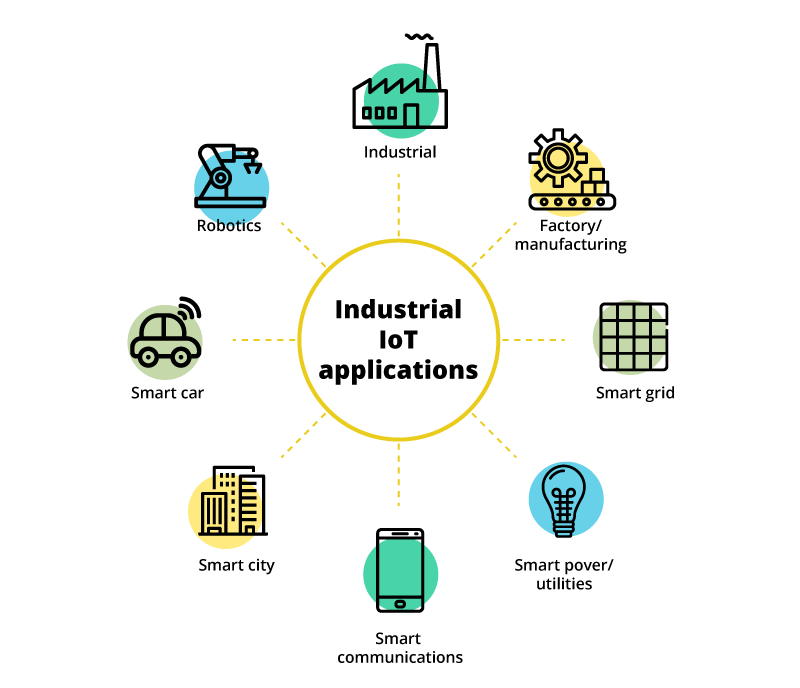

At winAMR we also offer technology-driven process for Industrial Internet of Things (IIoT). When IoT is used in an industrial or manufacturing process, it is automatically termed as IIoT. IIoT otherwise known as Industry 4.0 or Industrial Internet integrates big data technologies, machine learning, sensor data, machine-to-machine (M2M) communication to architect intelligent commercial-ready industrial equipment and facilities.

winAMR Industrial IoT platform will allow Industry to connect and process IoT data securely at a larger scale.

winAMR Industrial IoT (IIoT) is a network of devices which are connected through winAMR communications technologies. These devices analyze data, collect and exchange information to provide complete operational visibility to make rapid operational decisions that can enhance your business.

winAMR Industrial IoT increases visibility, enhances operational efficiency, reduces complexities and boosts productivity in the industry.

winAMR Industrial IoT Platform makes use of modern sensor technology to architect various industrial equipments with remote monitoring and maintenance capabilities. It helps in enhancing productivity, quality and safety.

Industrial manufacturing companies are facing strong demand to increase their productivity by realizing smart factories and smart manufacturing. With the advantages of winAMR IIOT solutions – IPCs, industrial automation and machine automation technologies, hardware-software integration and various other solutions – it’s now possible for Machine OEM’s to foster the development of Industry 4.0.

Large beverage processing companies to monitor the inventory and I/O flow. To gauge and optimize the performance of their various units. Alerts in case of any undetected leakage etc.

Monitor the water level and storage deficiency in supply chain.

It helps to save your employees from unnecessary expose to liquid and acids which hazardous in nature. Helps you to keep track of liquid gases needed to run your operation. Also monitor the used oil and waste liquid collection.

One of most important industry of liquid storage and supply. winAMR Real time IOT System can help here to monitor and track in real time your inventories as well as the delivery of products supplied to various retailers.

A smarter cold chain system, where monitoring devices can provide managers with live data about temperature and location, mitigating any problems along the chain before they arise.

& Made in India

& Made in India